Bearing Systems

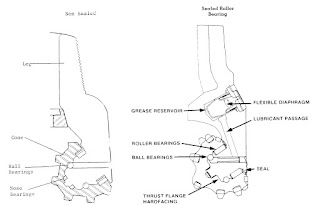

The first type of bearing system used with roller cone bits was a nonsealed,

roller-ball-friction bearing arrangement, utilizing rollers on the heel

of the journal. The primary load, or stress was exerted on these rollers, and

drilling fluid was used to lubricate the bearings. Bearing size was

maximized, since room for a seal was not required. The bearing surfaces

were machined and ground to very close tolerances to ensure dependable

service. This type of bearing system is also available with modifications for

air circulation and for use with a percussion hammer (Figure 3-6a).

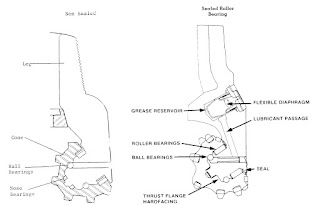

The next generation of bearing systems was a sealed roller bearing system,

having a sealed grease reservoir to lubricate the bearings. The bearing

system is composed of: 1) a roller-ball-friction or roller-ball-roller bearings

2) the seal, which retains the lubricant and prevents drilling fluid and

abrasive cuttings from entering the bearing cavities, 3) the shirttail is

designed and hardfaced to protect the seal, 4) a lubricant, an

elasto-hydrodynamic type, is used to ensure minimum friction and wear, 5)

the reservoir, which stores and supplies the lubricant to the bearings, and 6)

the vented breather plug, which transfers downhole fluid pressure against

the lubricant-filled flexible diaphragm to equalize pressures surrounding

the bearing seal (Figure 3-6b).

Figure 3-6a Figure 3-6b

There is, however, one serious drawback to the roller-ball-roller bearing

system. The primary cause of roller bearing failure is journal spalling,

which causes destruction of the rollers and the locking of the cone.

To remedy this, instead of the standard roller bearing assembly, the

“journal bearing” system utilizes solid metal bushings for direct cone to

journal contact. This offers a distinct mechanical advantage over roller

arrangements in that it presents a larger contact area at the load bearing

point. This distribution of the load eliminated the chief cause of roller

bearing assembly failure - spalling in the load portion of the bearing face.

Journal bearing systems in the tungsten carbide insert bits features a metal

bearing surface combined with a hardfaced journal and a lubricant.

Specialized seals and reliable pressure equalization systems keeps the

drilling fluid and formation contaminants out of bearings, and positively

seals the graphite-based lubricant inside the bearing. Precision fit of the

journal and cone distributes contact loading evenly throughout a nearperfect

arc. Bearing surfaces are finished to a carefully controlled surface

texture to ensure optimum lubrication.

The manufacturing of the journal bearing system consists of having the

journals either milled, grooved or pressed (depending on the bit company)

to accommodate the bushing. Then the bushings are inlaid on the journal.

Once the cone is fitted with teeth and gauge protection, the journal is then machine-pressed into the cone. To complete the seal between the cone and

the journal, special rings (seals) have been developed.

SealsThe first and still most popular seal is the radial seal (used mainly on the

sealed roller bearing bits). The radial seal is a circular steel spring encased

in rubber, which seals against the face of the shank and the face of the

cone. The newer “O” ring seal is considered the most effective seal. The

major problem confronting the “O” ring is tolerance, which must be precise

in order to maintain an effective seal.

An understanding of lubricants and lubricating systems is necessary for

successful drilling operations. The lubricating systems are essentially the

same, and are composed of an external equalizer located under the bit or on

back of the shanks, a grease reservoir with some sort of expandable

diaphragm to distribute the grease, and some sort of distribution system to

the bearings. In addition, there is a pressure relief valve to release any

trapped pressure, which might otherwise rupture the seals.

Pressure surges can be detrimental to these sealed systems. As pressure and

temperature increase, the viscosity of the lubricant increases. As a result,

the system cannot instantaneously compensate for abrupt changes in

pressure due to surges (going into the hole, making connections, etc.) and

small quantities of mud invade the system. With the close tolerance

necessary for effective sealing, mud solids can be damaging.

Adequate cleaning is even more important with sealed bearing bits. If

drilled cuttings are allowed to build up around the shirttail, seal damage

and premature bearing failure may result. Gauge protection is also

important to seal and bearing life, because seal damage can occur from

shirttail wear caused by inadequate gauge protection.

Any time a sealed bearing bit is rerun, the seals and shirttail should be

carefully checked for excessive wear or grooving.

To complete the journal-cone assembly, a positive seal is required to keep

drilling fluid out, while allowing the graphite lubricant in, which keeps the

bearings from overheating. The positive seal requires a relief valve to allow

escape of excess pressure, which can overload the seal and cause seal

failure.