Navi-Drill Mach 1C

The Mach 1C is a positive-displacement motor that develops high torque at

the bit at relatively low speed ranges (80-340 rpm). This makes it ideal for

directional applications, drilling with high weight-on-bit, navigation

drilling with roller cone or large cutter PDC bits, and coring operations.

The motor has a multi-lobe (5/6) rotor/stator configuration, which

generates higher torque than the 1/2 lobe motors, permitting more weighton-

bit and increasing the drill rate. Because the motor develops its power at

low speeds, it can improve bit performance without accelerating wear on

the bearings or cones.

A unique bearing assembly and improved elastomer compounds in the

stator have increased the Mach 1C’s hydraulic horsepower and extended

operating life. It also has a new rotor nozzling system that allows the motor

to be run at 50-100% over its maximum recommended flow rate without

exceeding maximum recommended motor speed. The additional mud

passes through the motor’s rotor, and flow rate can be adjusted by

interchanging nozzles. Higher rates offer improved hole cleaning and bit

hydraulics.

Although primarily a directional performance drilling motor, the Mach 1C

can also be used for straight-hole drilling.

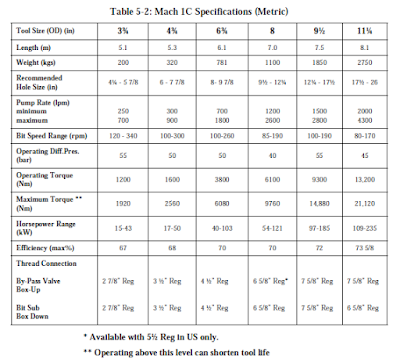

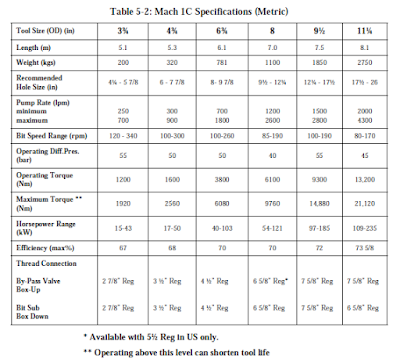

Tables 5-1 and 5-2 detail the Mach 1C specifications.

The Mach 1C is a positive-displacement motor that develops high torque at

the bit at relatively low speed ranges (80-340 rpm). This makes it ideal for

directional applications, drilling with high weight-on-bit, navigation

drilling with roller cone or large cutter PDC bits, and coring operations.

The motor has a multi-lobe (5/6) rotor/stator configuration, which

generates higher torque than the 1/2 lobe motors, permitting more weighton-

bit and increasing the drill rate. Because the motor develops its power at

low speeds, it can improve bit performance without accelerating wear on

the bearings or cones.

A unique bearing assembly and improved elastomer compounds in the

stator have increased the Mach 1C’s hydraulic horsepower and extended

operating life. It also has a new rotor nozzling system that allows the motor

to be run at 50-100% over its maximum recommended flow rate without

exceeding maximum recommended motor speed. The additional mud

passes through the motor’s rotor, and flow rate can be adjusted by

interchanging nozzles. Higher rates offer improved hole cleaning and bit

hydraulics.

Although primarily a directional performance drilling motor, the Mach 1C

can also be used for straight-hole drilling.

Tables 5-1 and 5-2 detail the Mach 1C specifications.