Types of Directional Patterns

The advent of steerable systems has resulted in wells that are planned and

drilled with complex paths involving 3-dimensional turns. This is

particularly true in the case of re-drills, where old wells are sidetracked and

drilled to new targets.

These complex well paths are harder to drill and the old adage that “the

simplest method is usually the best” holds true. Therefore, most directional

wells are still planned using traditional patterns which have been in use for

many years. Common patterns for vertical projections are shown on the following pages:

Features:·

Shallow kick-off point (KOP)

Build-up section (which may have more than one build up rate)

Tangent section

Applications:

Deep wells with large horizontal displacements

Moderately deep wells with moderate horizontal displacement, where intermediate casing

is not required

Features: There are several variations:

Shallow KOP - Build, hold & drop back to vertical

Build-up section - Build, hold, drop & hold (illustrated above)

Tangent section - Build, hold & continuous drop through reservoir

Drop-off section

Applications: Disadvantages:

Multiple pay zones - Increased torque & drag

Reduces final angle in reservoir - Risk of keyseating

Lease or target limitations - Logging problems due to inclination

Well spacing requirements

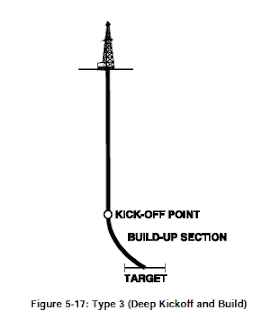

Deep wells with small horizontal displacements

Features:

Deep KOP

Build-up section

Short tangent section (optional)

Applications:

Appraisal wells to assess the extent of a newly discovered reservoir

Repositioning of the bottom part of the hole or re-drilling

Salt dome drilling

Disadvantages:

Formations are harder so the initial deflection may be more difficult to achieve

Harder to achieve desired tool face orientation with downhole motor deflection assemblies

(more reactive torque)

Longer trip time for any BHA changes required

On multi-well platforms, only a few wells are given deep kick-off points,

because of the small slot separation and the difficulty of keeping wells

vertical in firmer formation. Most wells are given shallow kick-off points

to reduce congestion below the platform and to minimize the risk of

collisions.

The advent of steerable systems has resulted in wells that are planned and

drilled with complex paths involving 3-dimensional turns. This is

particularly true in the case of re-drills, where old wells are sidetracked and

drilled to new targets.

These complex well paths are harder to drill and the old adage that “the

simplest method is usually the best” holds true. Therefore, most directional

wells are still planned using traditional patterns which have been in use for

many years. Common patterns for vertical projections are shown on the following pages:

Features:·

Shallow kick-off point (KOP)

Build-up section (which may have more than one build up rate)

Tangent section

Applications:

Deep wells with large horizontal displacements

Moderately deep wells with moderate horizontal displacement, where intermediate casing

is not required

Features: There are several variations:

Shallow KOP - Build, hold & drop back to vertical

Build-up section - Build, hold, drop & hold (illustrated above)

Tangent section - Build, hold & continuous drop through reservoir

Drop-off section

Applications: Disadvantages:

Multiple pay zones - Increased torque & drag

Reduces final angle in reservoir - Risk of keyseating

Lease or target limitations - Logging problems due to inclination

Well spacing requirements

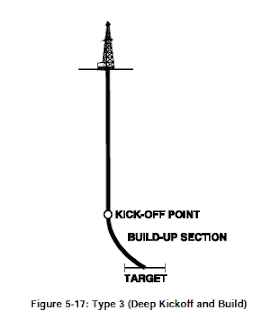

Deep wells with small horizontal displacements

Features:

Deep KOP

Build-up section

Short tangent section (optional)

Applications:

Appraisal wells to assess the extent of a newly discovered reservoir

Repositioning of the bottom part of the hole or re-drilling

Salt dome drilling

Disadvantages:

Formations are harder so the initial deflection may be more difficult to achieve

Harder to achieve desired tool face orientation with downhole motor deflection assemblies

(more reactive torque)

Longer trip time for any BHA changes required

On multi-well platforms, only a few wells are given deep kick-off points,

because of the small slot separation and the difficulty of keeping wells

vertical in firmer formation. Most wells are given shallow kick-off points

to reduce congestion below the platform and to minimize the risk of

collisions.