Calculating BHA Weight With Drill Pipe In Compression

This means that on high-angle wells in small hole sizes, a fraction of the

weight on bit can safely be provided by having drill pipe in compression. It

is suggested that 90% of the critical buckling force be used as the

maximum contribution to the weight on bit from ordinary drill pipe.

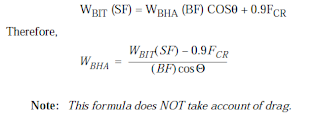

Denoting the total air weight of the BHA by WBHA the weight on bit by

WBIT and the critical buckling load by FCR, we have:

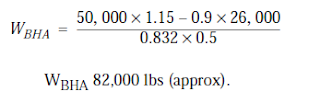

Continuing example 4.5, recalculate the weight of the BHA required

(assuming some drill pipe is to be run in compression).

Suppose we are using New 5-inch Grade E drill pipe with 4.5-inch IF

connections.

Referring to the table for 5-inch drill pipe in a 12.25-inch hole, we see that

the critical buckling load at 60° inclination is approximately 26,000 lbs.

Our formula then gives:

Thus, a total air weight of 82,000 lbs is required. This is much more

feasible than the value of 138,000 lbs which was previously calculated.

This means that on high-angle wells in small hole sizes, a fraction of the

weight on bit can safely be provided by having drill pipe in compression. It

is suggested that 90% of the critical buckling force be used as the

maximum contribution to the weight on bit from ordinary drill pipe.

Denoting the total air weight of the BHA by WBHA the weight on bit by

WBIT and the critical buckling load by FCR, we have:

Continuing example 4.5, recalculate the weight of the BHA required

(assuming some drill pipe is to be run in compression).

Suppose we are using New 5-inch Grade E drill pipe with 4.5-inch IF

connections.

Referring to the table for 5-inch drill pipe in a 12.25-inch hole, we see that

the critical buckling load at 60° inclination is approximately 26,000 lbs.

Our formula then gives:

Thus, a total air weight of 82,000 lbs is required. This is much more

feasible than the value of 138,000 lbs which was previously calculated.