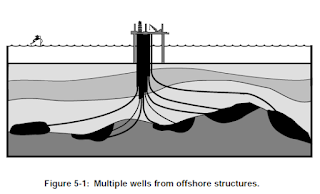

Multiple wells from offshore structures

The most common application of directional drilling techniques is in

offshore drilling. Many oil and gas deposits are situated well beyond the

reach of land based rigs. Drilling a large number of vertical wells from

individual platforms is both impractical and uneconomical. The obvious

approach for a large oilfield is to install a fixed platform on the seabed,

from which many directional boreholes can be drilled. The bottomhole

locations of these wells are carefully spaced for optimum recovery.

In conventional development, wells cannot be drilled until the platform has

been constructed and installed. This can mean a delay of several years

before production begins. Such delay scan be considerably reduced by predrilling

some of the wells through a subsea template while the platform is

being constructed. These wells are directionally drilled from a semisubmersible

rig and tied back to the platform once it has been installed.

The most common application of directional drilling techniques is in

offshore drilling. Many oil and gas deposits are situated well beyond the

reach of land based rigs. Drilling a large number of vertical wells from

individual platforms is both impractical and uneconomical. The obvious

approach for a large oilfield is to install a fixed platform on the seabed,

from which many directional boreholes can be drilled. The bottomhole

locations of these wells are carefully spaced for optimum recovery.

In conventional development, wells cannot be drilled until the platform has

been constructed and installed. This can mean a delay of several years

before production begins. Such delay scan be considerably reduced by predrilling

some of the wells through a subsea template while the platform is

being constructed. These wells are directionally drilled from a semisubmersible

rig and tied back to the platform once it has been installed.